| SMART DYEING,CHOOSE K&GREEN |

K&GREEN INDUSTRIES LIMITED, established in 2011, is a manufacturer and trader specialized in the research, development and production of dyeing machine. All of our products comply with international quality standard and are greatly appreciated in a variety of different markets throughout the world.

A NEW GENERATION OF AIRFLOW & OVERFLOW DYEING MACHINE

Today, the field of textile finishing faces enormous environmental challenges. Significant increases in the cost of water and effluent treatment, plus pressure to conserve resources, call for introspection of the efficiency and production process.

The new Q8, with its excellent running conditions, optimum use of inputs and reduced process time, is suitable for a variety of woven and knitted fabrics, and other blends from light to heavy structures. The new Q8 represents a sound investment for any dye house, at the same time ensures minimum environmental impact and ongoing sustainability. The achievements of substantial savings of water and energy resource consumption have amortised capital investment to customers and created a strong financial competitiveness through maximum cost-effective productivity with uniform quality.

With its increased productivity and enhanced reliability, the Q8 offers new perspectives and opportunities for all progressive textile companies.

K&GREEN’s products are greatly appreciated in a variety of different markets throughout the world.

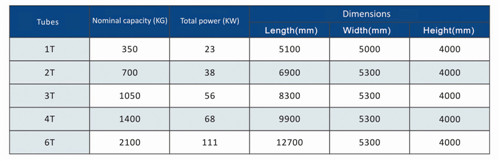

TECHNICAL SPECIFICATIONS

Technical details

● Liquor ratio starting at 1: 2~3.5

● Frequency-controlled high efficient air blower

● Frequency-controlled pump motor

● Variable winch with individual drive. Variable winch drive for fabric speeds up to 700m/min

● Low friction air atomization nozzle

● Teflon plate in fabric chamber

● Loads-adjustable fabric chamber

● Faster unloading and plaiting device

● Rope circulation control

● Seam detector

● Electro-pneumatic-operated valves

● Electronic measurement of liquor level

● Touch-screen controller

● Smart dose system-programmable, automated dosing of dyes and chemicals using readily adjustable parameters and bypass circulation

● Easy fabric-loading without a lead cloth

● Synchronised dyeing - optimized fabric circulation by automatically synchronising winch speed and nozzle pressure

- Appropriate nozzle pressure in every stage of the program

- Positive winch transport

- Reproducible adjustments

● Operating temperature up to 98℃or 140℃

● Nominal chamber capacity of 350kg

● Simplification of dyeing programs by use of variables

● Can be independent or combined use of airflow or overflow dyeing system

- Can be used independent dyeing easy curled knitted fabric

- Can use a combination of dyeing all kinds of knitted and woven fabric

- Solution to dyeing polyester fabrics with fine wrinkles and width

- Wash water time can significantly shorten and reduce energy consumption

● Salt dissolving-dry fill

● Self-cleaning filter

● Stock tank - automated stock tank for preparation of the complete process baths

● HT-Draining

SPECIAL FEATURES

● Contact-free dyeing-fabric sits above the liquor level

● Draining<85℃

● Quick stop

- Machine stops within 1sec, avoiding tangling and slippage

● Rope ABS

● Minimised selvedge curling

● Smooth fabric handling

● iJBox - optimised fabric transport

The new Q8 is suitable for a variety of woven and knitted fabrics.

|

| 相关文章 |